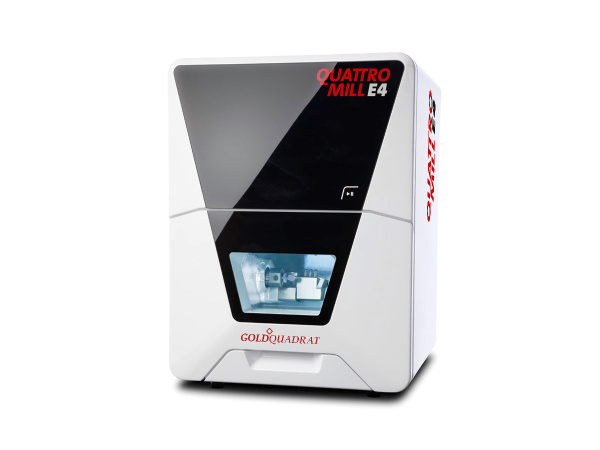

Product description

The GQ Quattro Mill E4 is the innovative milling machine for easy entry into same-day dentistry. The E4 is a true multi-talent, as it can grind wet as well as mill dry on four axes. The absence of compressed air allows maximum freedom in the choice of installation location and results in extremely favourable operating costs. The E4 makes it easy to enter chairside production of dental restorations and offers maximum freedom. It fits perfectly into all workflows.For wet processing of glass ceramics or composites with a ceramic content, the E4 works with a closed liquid circuit, the PUREWATER technology, and therefore does not require any abrasive additives. This makes disposal problem-free and reduces running costs. In dry machining, materials such as zirconium oxide, PMMA and various composites can be milled without cooling water and without compressed air.

Switching between wet and dry machining is uncomplicated: A simple change of the tank for wet machining or the container for dry machining is sufficient. A special filter mat in the liquid tank ensures that the tank is chip-free.

Thanks to its low weight of only 28 kg and its complete freedom from compressed air, the E4 offers maximum flexibility in placement and convinces with first-class results!

A special innovation of the E4 is its freedom from compressed air: the E4 requires neither an external compressed air connection nor a built-in compressor. This is made possible by our patent-pending AIRTOOL. The turbine blades of the AIRTOOL generate a strong air flow due to the high speeds of the high-frequency spindle, which keeps the workpiece free of chips and dust. These are removed by the suction system.

In addition, the GQ Quattro Mill E4 is very easy to operate thanks to the licence-free DENTALCAM software with DIRECTMILL Technology supplied. This has an open interface to all scanners and materials.

General

- fields of application: Wet/dry machining

- Materials: composites, plastic/wax, glass ceramic, zirconium

◦blocks up to 45 × 20 × 20 mm - Indications: Crowns, bridges, inlays, onlays, veneers, zirconium abutments, screw-retained crowns.

- holding systems: integrated block holder

Basic

- system construction: stable welded aluminium construction

- housing: white high-gloss lacquer · lift door opening upwards to the working area

- Number of axes: 4

- Linear axes X-/Y-/Z-axis: precision ball screws · motors with resolution < 1 μm · ground precision guideways made of high-alloy steel · repeatability steel · repeat accuracy ± 0.003 mm

- A-axis rotation: angle of rotation: +190° to -10

- Control electronics: 5-axis simultaneous control electronics with continuous path and dynamic precalculation · hardware real-time operating system with standardised instruction set · FPGA-integrated processor · updatable hardware hardware · real-time

path calculation and real-time ramp calculation via dedicated hardware engines in the FPGA · four-quadrant control of the motors for particularly smooth running · multiple digital I/Os for controlling the peripherals integrated inverter for synchronous and asynchronous motors,electronic cut-off detection · Ethernet and USB interfaces - Lighting: Backlit work area with RGB LED lighting and status display

Spindle

General: High-frequency spindle with electromechanical tool change

Speed: up to 60,000 rpm

Power: Output power (Pmax): 800 Watt · peak power (S6): 400 Watt · continuous power (S1): 300 Watt

Bearing: 2-fold hybrid ceramic ball bearing

Collet: for tools with 3 mm shank diameter and max. 40 mm overall length

Automation

Tool change: Removable tool magazine for 6 tools with additional individual place for an AIRTOOL · length measurement

and tool breakage control via precision measuring probe · access via working area door, safety-locked

Access to combi compartment: direct insertion of coolant tank or (optional) dryer tank in compartment under the work area.

Machining modes

Wet: 2 liquid nozzles on the spindle · integrated reservoir for coolant · PUREWATER Technology: no abrasive additives required

Dry: Compressed air-free operation by using AIRTOOLs · hose connection for external suction cup on the housing wall

· 24 V switching output for controlling suction units · optional drying container required

Technical data

- Dimensions (W/D/H): closed approx. 360 x 370 x 490 mm, open approx. 360 x 420 x 490 mm

- leg spacing (W/D): 270 x 268 mm

- Weight: approx. 28 kg

- Suction: Filter class M, 2,500 l/min air volume , 200 hPA negative pressure.

- Power supply: 100 to 240 V, 50/60 Hz, 500 Watt

- Collet: for tools with 3 mm shank diameter and max. 40 mm total length

Connection requirements

Compressed air: -

Power supply: 100-240 volts - 50/60 Hz, 500 watts

Extraction: Filter class M, 2,500 l/min air flow, 200 hPa negative pressure.

Data: 10/100/1000 MBit/s BaseT port (automatic detection) Ethernet via RJ-45 socket

Scope of delivery

CAM softwareDENTALCAM

Holder systems

Block holder (integrated)

Accessories Spindle Service Set

- Calibration set incl. outside micrometer

- Tool magazine inserts (1 piece)

- Torx screwdriver set

- Torque screwdriver set 1.5 Nm

- AIRTOOL for PMMA/wax

- drill (tool positions)

- Cleaning brush and microfibre cloth

- TecPowder

- Foam filter

- Network cable

- Ethernet network cable

- Instruction manual

Artikelmerkmale

Manufacturer

VHF

Product type

Milling machine